EMS/OEM

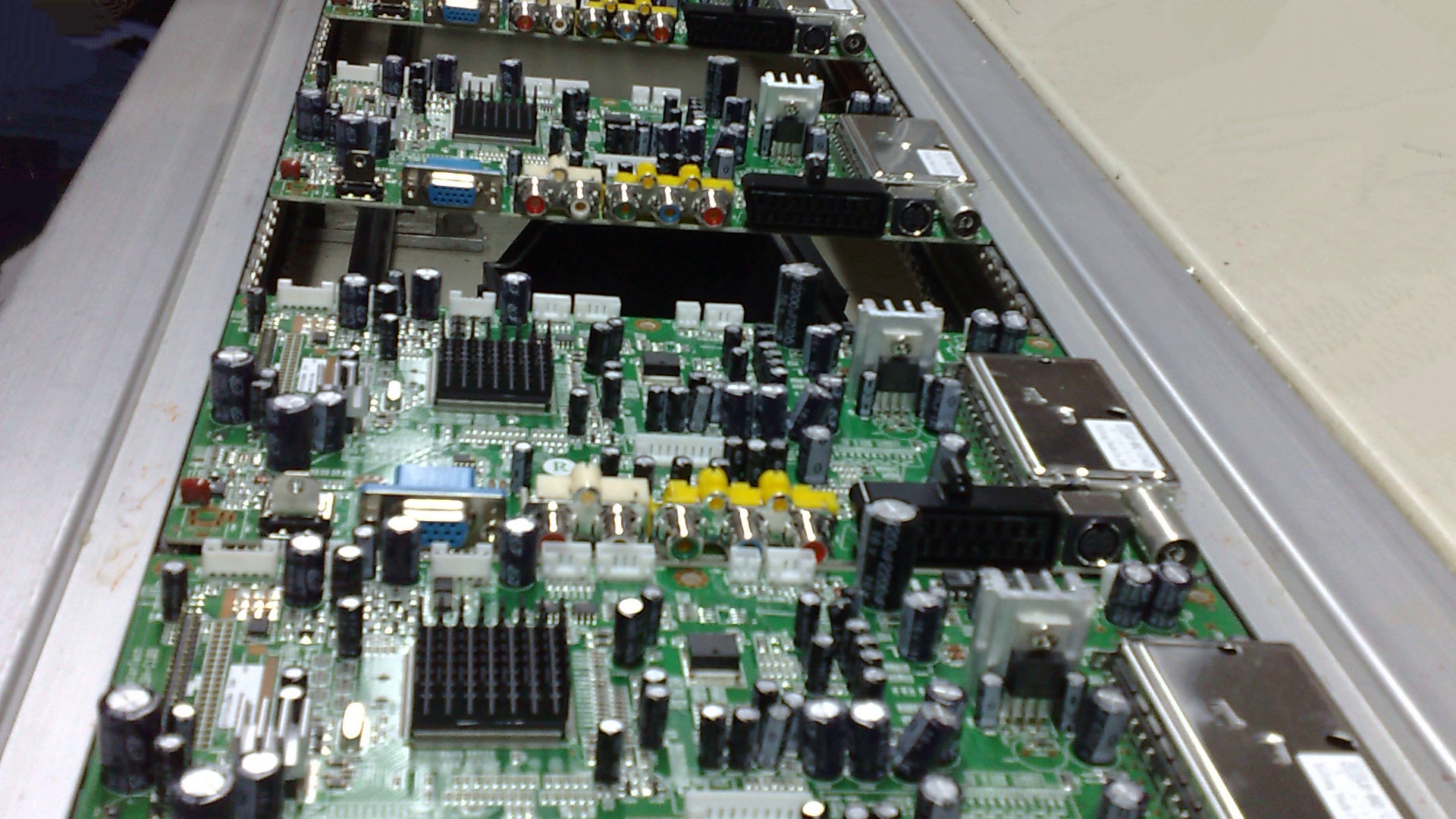

PROBOND's expertise in Printed Circuited Board Assembly spans several years. From low-volume and high-mix to advanced high-volume manufacturing, PCB Assembling is PROBOND's core competency.

Our ultimate goal is to provide customers with quality products and on-time delivery. To maintain our position as a leader in this field we strive to maximize yields and minimize defects.

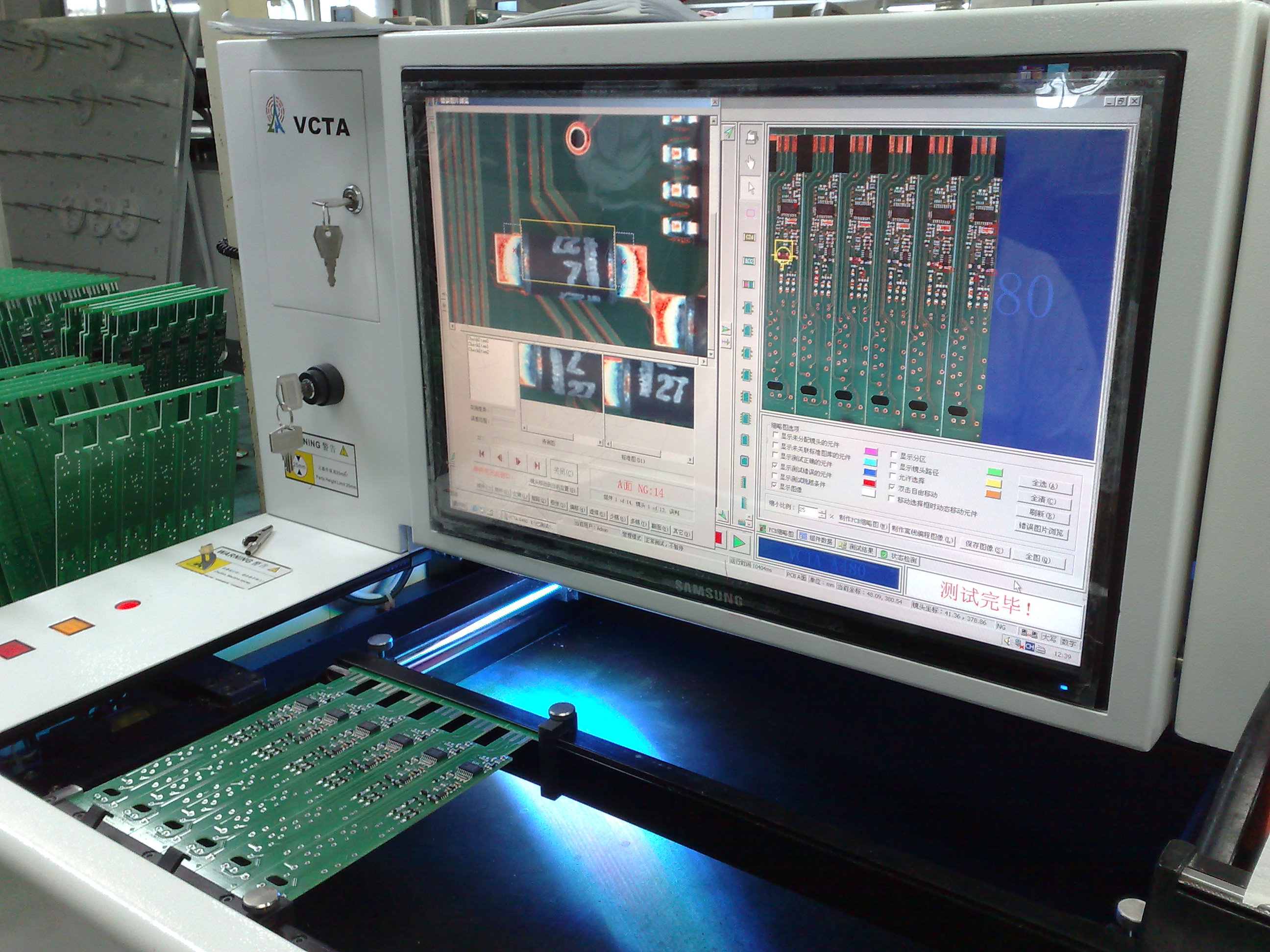

Our European engineers guarantee quality of service. This quality is exhibited by high automation, speed, accuracy, repeatability, flexibility, precision and easy set up.

Throughout the manufacturing process, from bare board through reflow to final inspection and testing, PROBOND's "quality and data tracking" methodology provides customers with agile, flexible and low-cost manufacturing solutions.

PCB Manufacturing Technologies: - SMD/THT/Assembling - COB - Lead free assembling